Nestle Professional boosts manufacturing innovation – starting with waste-saving Hot Chockee cups

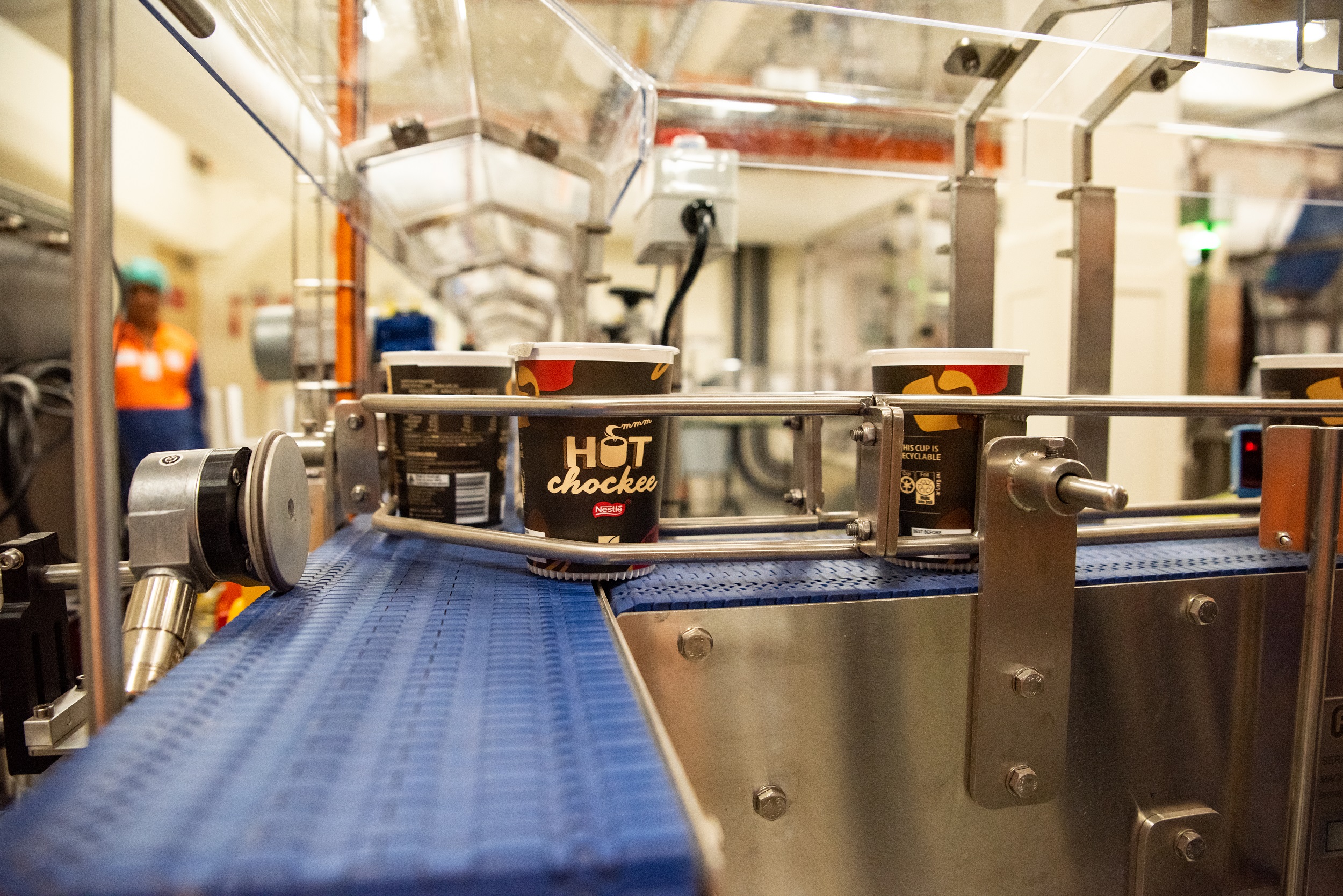

NESTLE Professional has invested more than $2.5 million in its Smithtown factory in NSW, to bolster local manufacturing and support collaborative product developments – starting with a new recyclable Hot Chockee cup.

A partnership between Nestlé Professional and 7-Eleven has focused on the innovative development of a recyclable cup, including the label and foil seal, now accepted through kerbside recycling. The result could save up to 95 tonnes of waste from entering landfill each year.

Nestlé Professional Oceania general manager Kristina Czepl said, “The recent investment into Smithtown factory has allowed us to collaborate on exciting new packaging solutions, like the Hot Chockee cup.

“It is a great example of working with likeminded partners to pioneer alternative materials to facilitate better recycling.

“In addition, the investment will see the factory produce up to 4.7 million cups of Hot Chockee over the next 12 months.”

7-Eleven Head of Sustainability Fiona Baxter said, “We are incredibly proud to continue our partnership with Nestlé Professional and invest in innovative packaging solutions. Our new 7Eleven Hot Chockee still has the same delicious taste, made and packed in Australia, with approximately 68 percent of ingredients sourced locally.

“The cup is now recyclable via kerbside recycling services. All elements of the cup can be placed in kerbside mixed recycling. This innovation helps both Nestlé and 7-Eleven to continue to work together towards our packaging sustainability targets."

Since 1921, the Nestlé Smithtown factory has been an integral part of the Nestlé Professional Australian food and beverage manufacturing, home to Aussie favourites such as Milo , Nesquik and Nestlé Hot Chocolate.

The investment into Smithtown factory will enable Nestlé Professional and its partners to bolster new product development in Australia, Ms Czepl said.

ends

How to resolve AdBlock issue?

How to resolve AdBlock issue?