Australian fencing innovation going strong after 50 years

ONE of the world’s great innovations for rural properties, the Lightning Fence Dropper, is still going strong after it was developed in Australia more than 50 years ago. In fact, the company that makes it is experiencing higher demand than ever.

The Lightning Fence Dropper remains a mainstay Australia-wide for rural wire and post fencing, selling more than a million examples a year – its patented design and quality local manufacture has never been bettered – and now the device looks like being picked up internationally.

Basically, the Fence Dropper changes the nature of rural post-and-wire fencing, reinforcing it and introducing an ‘elasticity’ so it can withstand impacts from cattle, sheep and horses – even kangaroos. The units clip among the wires to keep them properly spaced, to provide a visible signal that a fence exists, and allowing a greater separation of posts, to save costs.

From the earliest days of wire fencing, both in Australia and in the US where it was also common on large farming properties, the earliest droppers succeeded because of low cost and speed of roll-out – but also regularly failed under impact from animals. Barbed wire fencing may have reduced that problem, but created damage problems of its own – as it proved far more expensive and troublesome to install.

The idea of a vertical wire ‘stay’ that would reinforce the fencing has been around for more than 150 years and was applied with some success. The fundamentals were well understood and almost 150 different fence dropper designs were patented in Australia from the 1890s to about 1914. Yet fewer than 50 were ever manufactured and sold in large numbers.

It was not until the Lightning Fence Dropper was developed in Australia the 1960s, made of newly developed galvanised high-tensile steel and in an efficient shape like that of a stylized lightning bolt, easy to lever on with a purpose-made tool, that the system really made its mark.

With the development of the Lightning Fence Dropper and its patent granted on October 9, 1968 – to its developer, the late Roger Sachs of Mayne Industries in Brisbane – manufacturing triggered up and the device had a huge impact on farm fencing around the country. The name has become generic, with farmers often referring to the devices simply as ‘lightning droppers’.

The design was originally manufactured and sold by Mr Sachs’ company National Nails Pty Ltd in the 1960s, which later became Hi Tensile. The new device had major advantages over previous fence droppers, which were awkward to manufacture and time consuming to install.

“If you weren’t careful you would staple your fingers or poke your eyes out when manufacturing or installing those earlier ones,” said Nick Sachs, son of inventor Roger, who took over the running of National Nails/Lightning Fence droppers after the untimely passing of his father in 1992. “Dad’s invention changed all that and made it quick, easy and safe.”

By 1998, with the help of a Brisbane Marketing Company, the Lightning Fence Droppers part of the business expanded its distribution network and increased sales to more than 1,000,000 droppers each year throughout Australia.

Like all great manufacturers, the business has undergone a continuous improvement process and today, where five giant machines once churned out the droppers in their millions, two custom-developed machines do the job with more precision and in greater numbers than ever before.

As the science of agricultural fencing has developed, so has the use of the fence droppers.

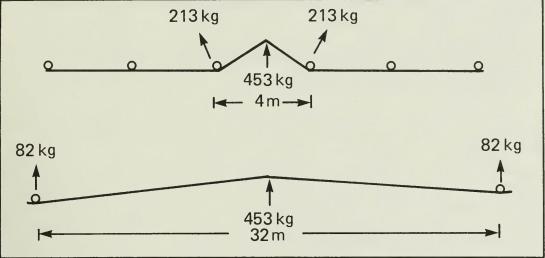

A good example is a bull striking a fence with post spacings of 4m. With approximately 450kg of force, it can impose a load of over 200kg of lateral force on the posts.

If that same bull hits a fence with its posts spaced 30m apart, the impact felt at the post will be around 80kg. Roughly 80 percent less.

A wire subjected to a tension less than its yield point will return to its original length when tension is removed. However, if the tension exceeds the yield point, the wire will stretch permanently.

Driving staples tightly against the wire on line posts interferes with the wire’s elasticity and reduces the wire’s tolerance to impacts.

“The steel we use to make our Lightning Fence Droppers is basically the same used in piano wire,” Mr Sachs said.

“It is a high tensile galvanised spring steel, with incredible yield strength. This allows the wire to return to its original shape after significant bending or twisting. No bull!”

Mr Sachs said Lightning Fence Droppers were still the only fence dropper that could be bent end to end and have it return to its original yield and strength.

“It remains the only fence dropper guaranteed for the life of the fence, too,” he said.

The design and quality of material is still unmatched in field performance by imported imitators, many of which have attempted to wrest the market from the Australian company in recent years.

“Our best advocates are our long-term customers,” Mr Sachs said. “Some of our existing clients are farmers that tell us they have had our fence droppers working for them for over 40 years.

“Some of our best new customers are those that have taken the advice of these old timers, after wasting money on some cheaper alternatives that have failed in the field and caused thousands of dollars of recovery damage.”

South Australian farmer Rob Cooper, of Waitipinga, said he had placed his faith in Lightning Fence Droppers after extensive research.

“Lightning Fence Droppers have saved me thousands of dollars,” Mr Cooper said. “My existing eight-strand plain wire fences were not Dorper-proof … Dorpers (a hardy and robust breed of sheep) are renowned for being hard on fences.

“They would hardly break stride to get through the plain wire fences previously. These droppers have 100 percent sheep proofed my existing fences at a fraction of the price of ring lock. They are very quick to install, too. Very impressed. Beautifully designed product.”

Apart from the Lightning Fence Dropper’s great reputation in reliable stock management, it has also proven its worth in handling natural disasters such as floods – and it was put to the extreme test in 2011 in Queensland.

“A lot of fencing got wiped out from raging flood waters – even those with fence droppers – but after it was all over, the farmers told us that they had to repair fewer fences that had our Lightning Fence Droppers deployed,” Mr Sachs said. “That was an unexpected, but very heartening result.”

He put the advantages of the Lightning Fence Dropper down to the quality of the steel and the way it was manufactured, allowing much greater elasticity and strength than other systems offered. The company also makes compatible steel and composite posts that are even stronger than the usual wooden or star-picket units and much quicker to deploy as smaller holes can be dug, offering greater spans.

“At the end of the day, when you are managing these vast properties, you want to do the fencing once, as quickly and cost-effectively as possible, and know you can rely on it to keep your stock in check with little chance of injury to your stock,” Mr Sachs said. “You also want to be able to trust that it will do its job long into the future with little maintenance.

“That’s been the great advantage of the Lightning Fence Dropper over the past 50-or-so years, it’s stood the test of time and it is still out-performing the knock-offs and other units that claim to do the same thing.

“What we have to do is keep showing and reminding our rural property owners that this is the Australian invention that not only set the benchmark 50 years ago, it has outlasted and out-performed all other solutions ever since. It is as transformative and cost-effective over the long term today as it has ever been.”

http://www.austehc.unimelb.edu.au/tia/844.html

ends

How to resolve AdBlock issue?

How to resolve AdBlock issue?