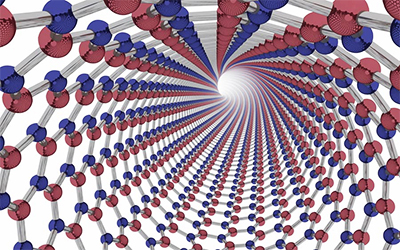

Victorian company first to develop nanotubes

A VICTORIAN business will be the first in the world to commercially develop one of the strongest fibres in existence – a product with applications in the aviation, automotive, aerospace, power, electronics and health industries.

BNNT Technology has received a $1.4 million Advanced Manufacturing Growth Fund grant to help produce its Boron Nitride Nanotubes on an industrial scale.

So far the super fibres have only been produced in small laboratory-scale quantities.

Federal Minister for Industry, Science and Technology Karen Andrews, said BNNT was one of 15 small and medium-sized businesses that will receive grants in the second and final round of the Advanced Manufacturing Growth Fund.

“These grants will help companies transition from traditional, heavy processes to advanced manufacturing of higher value products, creating new opportunities and new jobs,” Ms Andrews said.

“Nearly $19 million is being distributed in Victoria and South Australia to help industries adjust in the two states most affected by the closure of vehicle manufacturing.

“This is expected to result in an additional investment of $45 million from the successful businesses.

“These businesses show the potential of Australian manufacturing: our firms and our workers can make high-tech, high-value products that can compete in a global market,” Ms Andrews said.

“These grants are an example of business and government working together to ensure that our nation is at the cutting edge in the rapidly evolving manufacturing sector.”

Other successful applicants in the second and final funding round include South Australian companies Micro-X and Bickford’s and Victorian company Rutra.

Micro-X is a manufacturer of novel x-ray products for medical and security applications. The grant to Micro-X is to help develop locally produced components.

Bickford’s is a beverage manufacturer. The company will use the grant to help develop a liquid batching process that will enable faster flows and greater volume flexibility in production.

Rutra’s project will use 3D digital manufacturing in the production of custom-made orthotics in its Footwork Podiatric Laboratory.

Companies which received funding in the first round of grants have already started buying advanced manufacturing equipment and designing and preparing their factories for the changes.

For example, Redarc Australia, a defence supplier in South Australia, is already installing equipment it has purchased.

The Federal Government’s $47.5 million Advanced Manufacturing Growth Fund was established in the 2017-18 Budget as part of a $100 million package to support advanced manufacturing.

How to resolve AdBlock issue?

How to resolve AdBlock issue?