H3 Dynamics develops mobile hydrogen filling stations for UAVs

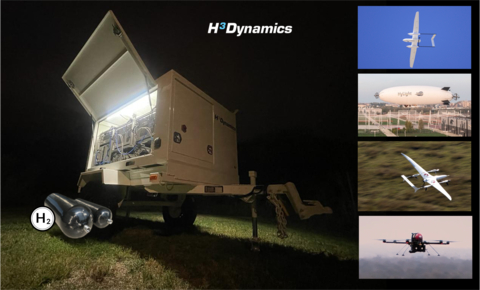

INTERNATIONAL hydrogen-powered aviation group, H3 Dynamics has developed the world’s first mobile hydrogen fuel station for hydrogen drones and UAVs of all shapes and sizes. The mobile stations are branded H2FIELD and they produce hydrogen on site and offer automatic refilling in the field.

The H3 Dynamics solution solves the problem of hydrogen access in remote locations by producing fuel on-site. The automatic storage tank filling system is easy to use and enables 24/7 operations.

Now H3 Dynamics – which has three regional headquarters in Singapore, Toulouse, France and Austin, Texas in the US – is looking to develop larger systems addressing airfield and airport operations.

“We are the evolutionary starting point to increasingly large hydrogen powered flight platforms, where testing, certification and regulatory approval challenges vary based on aircraft weight,” H3 Dynamics CEO and co-founder Taras Wankewycz said.

“We want to mature hydrogen technology in today’s existing uncrewed aviation market – and that includes working out hydrogen logistics and refueling systems.”

The H2FIELD system can service hydrogen-powered airships, multi-rotors, vertical take-off and landing UAS and various fixed wing systems.

H2FIELD’s rugged IP-65 trailer-based solution brings hydrogen production to different drone operation locations. It can also be dismounted as a permanent installation and connect to solar panel arrays.

H3 Dynamics can supply various configurations, with slow or fast charge options down to minutes per fill, a spokesperson said, “depending on client requirements”.

“H3 Dynamics’ system is extremely compact and can produce hydrogen on site – not just dispense it from other storage forms,” the spokesperson said.

“For hydrogen drone operators, H2FIELD-1 solves fundamental hydrogen accessibility in remote areas, unlocking a major logistical barrier for a growing base of hydrogen drone operators in industrial, defence, or even academic sectors. The only feedstock input is water.”

H3 Dynamics has been working on a first transatlantic hydrogen-electric flight using liquid hydrogen storage systems currently being tested in France with ISAE-SUPAERO in Toulouse. Last week H3 Dynamics announced its hydrogen propulsion partnership with French airship maker HyLight, and the week prior with Australian VTOL UAV producer Carbonix whose airframes are made by Quickstep, Australia’s innovative aerospace composites producer.

The spokesperson said 2023 would see more of these announcements as H3 Dynamics continues to transition battery-UAS manufacturers to hydrogen technologies.

According to the H3 Dynamics spokesperson, compared with batteries, hydrogen electric systems increase battery-drone flight durations by several orders of magnitude, “opening up many new possibilities in a market that is expected to grow five-fold to $100 billion by 2030”.

H2FIELD-1 marks the start of H3 Dynamics’ foray into hydrogen infrastructure solutions for small, unmanned and increasingly large aircraft, from airfields to airports – with increasingly large output power and hydrogen storage capabilities.

Taras Wankewycz said H3 Dynamics was on a mission to decarbonize aviation.

“While the commercial opportunities around passenger-scale hydrogen aviation propulsion will take many more years to mature, the company is following a ‘start small’ product and services roadmap that solves safety, technical, regulatory challenges by adding scale, weight and complexity over time.”

The company employs 94 team members from its three regional headquarters in Toulouse, Austin and Singapore. H3 Dynamics is a member of the Alliance for Zero Emission Aviation under the European Commission, Sustainable Aero Lab, the Lufthansa Cleantech Hub, the Paris Advanced Air Mobility Alliance, and Aerospace Valley in Toulouse

ends

How to resolve AdBlock issue?

How to resolve AdBlock issue?