Wiley wins Master Builders award for enviro ‘ingenuity’

EXTRA >>

A WORLD-LEADING biogas and water treatment plant, designed and constructed by Wiley, took out the award for Innovation in Environmental Management at the recent Queensland Master Builders Association (QMBA) State Awards.

It is the second award Wiley has won for the project, after taking home the same category at QMBA’s regional awards earlier this year. Wiley partnered with Australia’s largest meat processing company, JBS Australia, to create the self-sustaining biogas facility at JBS Australia’s Dinmore facility.

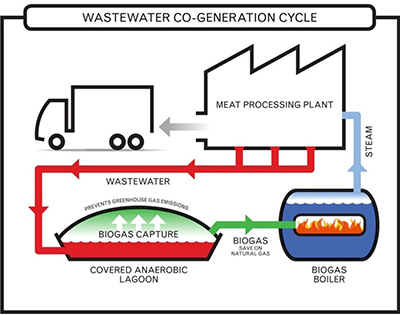

The plant captures cattle emissions to power an existing natural gas-fired boiler plant, reducing annual greenhouse gas emissions by 89 percent and saving more than $1 million a year on natural gas costs.

“Winning both the regional and state award for Innovation in Environmental Management is an exciting achievement for the company and a great reward for the team’s hard work and out-of-the-box thinking,” Wiley managing director Tom Wiley said.

“The company’s heritage as a global leader in food facilities and plant design, consulting, and construction has provided the Australasian business with unparalleled experience in complex builds and structures that lends itself to projects that others struggle to handle alone.

“Some structural developments are so complex that they need a fresh perspective to deliver a practical, effective, and in this case, an innovative solution – that’s something Wiley prides itself on.

“We’re also a human-centric organisation, which means our capabilities lie in the knowledge of our people to problem-solve and work in collaboration with clients and partners to deliver exceptional outcomes.

“Rather than shy away from complex projects, we actively seek them out to continually evolve our thinking, processes, and solutions.”

Wiley project director Graham Harvey said, “This is an industry benchmark demonstrating the reality of environmental processing solutions for heavy emission producers. It is a great win for Wiley, JBS Australia, and everyone involved.”

The project’s key solutions included construction of a new 20ML Covered Anaerobic Lagoon (CAL); covering of two existing Anaerobic Lagoons (AL) with high density polyethylene (HDPE) to capture biogas, and then burn the gas through the boiler to provide energy for the plant; installation of a biogas train to pipe biogas from the CALs to a central flare and then to the existing 10MW boiler; upgrade of waste water treatment plant (WWTP) with a new Dissolved Air Flotation (DAF) unit.

An in-depth profile of the JBS Dinmore project is available to read and download here: http://www.wiley.com.au/experience/biogas-recovery-project-gives-jbs-environmental-and-financial-edge

ends

How to resolve AdBlock issue?

How to resolve AdBlock issue?